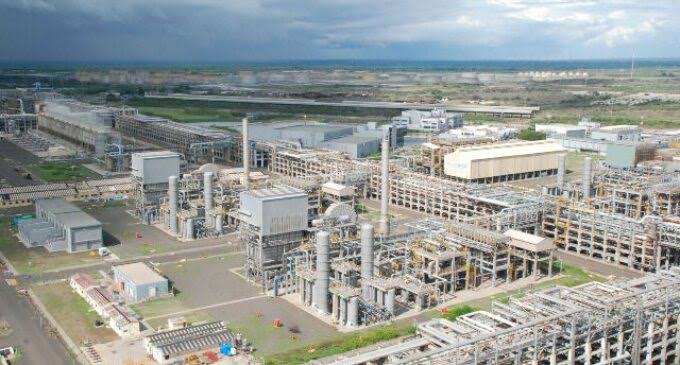

Oil refineries power the world, turning raw crude into the fuel, plastics, and chemicals that keep modern life moving. And standing at the very top of that global chain is a single complex: the Jamnagar Refinery in Gujarat, India.

Owned and operated by Reliance Industries Limited, Jamnagar is not just the largest oil refinery in the world; it’s also one of the most technologically advanced and integrated. With a capacity of over 1.24 million barrels per day, this refinery is so massive that it processes more oil daily than many countries consume in a week.

But beyond the numbers is a story of ambition, precision, and global significance.

In this in-depth guide, we’ll walk you through every corner of the Jamnagar Refinery, including how it came to be, how it works, who it serves, and where it’s headed next. If you’ve ever wondered what it takes to run the biggest refining operation on Earth, you’re in the right place.

Let’s step inside Jamnagar.

How the world’s largest refinery was built: the story of Jamnagar

The story of the Jamnagar Refinery, the largest refinery in the world, is rooted in vision, timing, and an audacious belief in India’s energy future. In the late 1990s, Reliance Industries Limited (RIL), under the leadership of Dhirubhai Ambani and later Mukesh Ambani, set out to build a facility that would not only meet India’s growing demand for petroleum products but also make the country a major exporter.

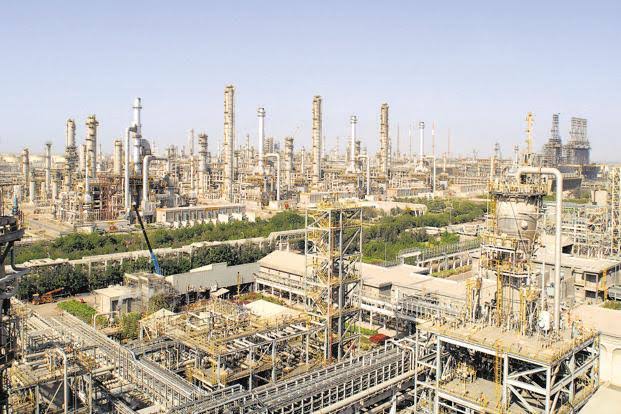

Construction began in 1996 on what was previously barren desert land in Jamnagar, Gujarat, a coastal state with direct access to the Arabian Sea. By 1999, the first phase of the refinery was completed, with a processing capacity of 668,000 barrels per day (bpd); it instantly became the largest grassroots refinery in the world at the time.

But that was only the beginning.

In 2008, Reliance commissioned a second, even larger refinery adjacent to the first one, located within a Special Economic Zone (SEZ). This second complex added 580,000 bpd of refining capacity. Together, the two complexes created the Jamnagar Refinery Complex, with a total capacity of 1.24 million barrels per day, making it the world’s largest refinery at a single location.

The project was notable for its speed and precision. Thousands of engineers, construction workers, and global contractors worked under tight deadlines. Reliance sourced equipment and expertise from around the world, including the U.S., Europe, and Japan to build what would become a benchmark in the refining industry.

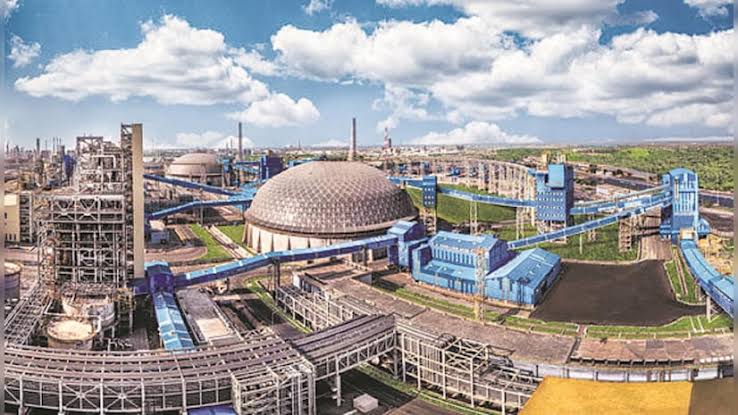

Jamnagar was designed not just as a standalone refinery but as an integrated petrochemical hub, enabling Reliance to maximize value from every drop of crude. It could process a wide variety of crude grades, including some of the heaviest and most sour types that many other refineries cannot handle efficiently.

Today, what started as a bold gamble is now a globally admired engineering feat, a fully integrated refining and petrochemical complex that fuels economies far beyond India’s borders.

Just how big is the world’s largest refinery?

The Jamnagar Refinery Complex in Gujarat, India, holds the title of the largest refinery in the world based on installed processing capacity. It refines up to 1.24 million barrels of crude oil per day, a figure that places it ahead of all other single-location refineries globally.

This capacity is made up of two integrated facilities:

- The Domestic Tariff Area (DTA) refinery, commissioned in 1999

- The Special Economic Zone (SEZ) refinery, commissioned in 2008

Together, they span over 7,500 acres of land. The site includes multiple processing units, storage tanks, utility systems, and support infrastructure. It also features:

- Crude distillation units

- Fluid catalytic cracking (FCC) and delayed coking units

- Hydrocrackers, visbreakers, and alkylation units

- Petrochemical units for plastics and intermediate chemicals

The complex is designed to handle a wide range of crude oil grades, from light sweet to heavy sour. This gives it operational flexibility, allowing it to adapt to changing market conditions and crude oil availability.

In addition to refining, the facility includes:

- A dedicated marine terminal at Sikka Port for crude imports and product exports

- Large tank farms for crude and finished products

- Rail and road links for inland distribution

- Utility systems such as power generation, desalination, and water treatment

Jamnagar’s scale is not just in its refining numbers but also in its integration. By combining fuel production with petrochemicals and logistics, it functions as a full-spectrum processing hub. Its products are distributed across India and exported to multiple regions, including Asia, Africa, Europe, and the Americas.

What the Jamnagar refinery produces

The Jamnagar Refinery, recognized as the largest refinery in the world, processes a wide variety of crude oils into multiple finished and intermediate petroleum products. With its high complexity and configuration, it can handle both light sweet and heavy sour crude, making it capable of producing a broad range of outputs for domestic and international markets.

Main Products Refined at Jamnagar Include:

- Gasoline (Petrol)

- Diesel

- Jet fuel (ATF)

- Liquefied Petroleum Gas (LPG)

- Naphtha

- Kerosene

- Sulfur

- Petroleum coke

- Bitumen

In addition to fuels, the refinery integrates with Reliance’s petrochemical units, producing key raw materials for plastics and industrial manufacturing. These include:

- Ethylene

- Propylene

- Paraxylene

- Polypropylene

- Benzene

- Linear alkylbenzene (LAB)

This level of integration between refining and petrochemicals is a core feature of the Jamnagar complex. It allows Reliance to extract maximum value from each barrel of crude, converting both light and heavy fractions into useful products. It also reduces waste and makes production more economically efficient.

Jamnagar follows a high-conversion refinery model, meaning it uses advanced secondary processing units, such as hydrocrackers and cokers to break down heavier crude components into lighter, more valuable products. This is especially important when processing lower-quality or sour crude.

The output from the complex is used to supply fuel across India and exported to more than 100 countries, making Jamnagar an important node in the global fuel supply chain. Its product slate meets Euro V and VI standards, enabling it to serve markets with strict environmental regulations.

Overall, the Jamnagar Refinery operates as a multipurpose production site, delivering both transport fuels and feedstock for the petrochemical industry.

World-class technology at the largest refinery in the world

Running the largest refinery in the world requires more than just space and equipment, it demands a high level of technological integration across operations, safety, and efficiency. The Jamnagar Refinery has been developed using a mix of conventional refining units and advanced digital systems to support continuous, large-scale production.

Core refining technologies

Jamnagar features some of the most complex configurations in the refining industry, including:

- Crude Distillation Units (CDUs) for initial crude separation

- Fluid Catalytic Cracking (FCC) units to convert heavy oils into lighter products like gasoline

- Hydrocrackers for upgrading heavy fractions using hydrogen

- Delayed Cokers to break down residual oils and produce petroleum coke

- Alkylation and isomerization units for high-octane fuel production

- Desulfurization units for producing cleaner fuels

These units allow for high conversion rates, meaning a larger percentage of the crude oil is turned into high-value products instead of low-value residue.

Digital systems and automation

The refinery complex includes:

- Distributed Control Systems (DCS) and Advanced Process Control (APC) for monitoring and managing operations

- Real-time data systems for performance tracking and process optimization

- Predictive maintenance tools to reduce downtime and equipment failure

- Integration of Internet of Things (IoT) devices across pipelines, tanks, and control rooms

Technical collaborations

Jamnagar’s setup has benefited from collaboration with multiple global technology providers, including:

- UOP (Honeywell) – licensed technologies for hydroprocessing and aromatics

- Chevron Lummus Global, Shell Global Solutions, and others – for specific cracking and coking units

- ABB, Siemens, and similar firms – for electrical and control systems

Utilities and support systems

Beyond the refining units themselves, Jamnagar includes:

- On-site power generation plants for uninterrupted electricity

- Water desalination facilities, due to its coastal location

- Effluent treatment systems to manage and recycle industrial waste water

These systems ensure the complex remains self-reliant and minimizes environmental impact where possible.

In short, the Jamnagar Refinery relies on a combination of proven refining infrastructure and digital tools to manage operations efficiently and meet global product quality standards.

Why Jamnagar was the perfect location for the largest refinery in the world

The decision to build the world’s largest refinery in Jamnagar, a coastal city in Gujarat, India, was based on a combination of logistical, geographic, and economic factors. While the scale of the refinery is massive, its location plays a key role in enabling smooth, cost-effective operations.

- Proximity to the Arabian Sea

Jamnagar lies on the western coast of India, with direct access to the Arabian Sea. This makes it ideal for importing large volumes of crude oil and exporting refined products to global markets. Reliance Industries developed the port at Sikka, just outside the refinery complex, to handle:

- Crude oil imports from the Middle East, Africa, and Latin America

- Outbound shipping of refined fuels to Asia, Europe, and the Americas

The port is equipped with Single Point Mooring (SPM) systems and marine terminals that accommodate Very Large Crude Carriers (VLCCs), allowing for cost-efficient ocean transport.

- Logistical infrastructure

Jamnagar is well-connected to India’s national highway and railway network. This enables distribution of fuel and petrochemicals across the country. Additionally, pipelines link the refinery to northern and western India and rail terminals and road tankers serve domestic demand efficiently

- Availability of Land

The region offered enough undeveloped land for Reliance to construct a large, integrated complex. Over 7,500 acres were secured for the two refinery units, support facilities, storage tanks, townships, and utility services.

- Industrial water access

Despite being a dry region, the proximity to the sea enabled the use of desalination plants to meet industrial water needs. Jamnagar houses some of India’s largest seawater desalination facilities to supply the refinery and associated infrastructure.

- Policy and industrial support

Gujarat has long been one of India’s most industry-friendly states, known for proactive governance and infrastructure investment. The Special Economic Zone (SEZ) status of one of the refineries provides tax and regulatory benefits for exports. This made the region more attractive from an operational and financial standpoint.

- Energy and utilities

With on-site power generation and strong grid connectivity, the refinery benefits from reliable energy supply. The ability to operate independently is especially important given the size and complexity of its systems.

In summary, Jamnagar’s coastal location, infrastructure access, policy incentives, and industrial resources made it a strategic choice for building a refinery of this scale. Its placement supports both domestic supply and efficient export operations.

The people behind the refinery: workforce, infrastructure, and life at Jamnagar

Operating the largest refinery in the world requires a coordinated effort from thousands of skilled workers, engineers, managers, and technical staff. The Jamnagar Refinery Complex functions like a self-contained city, built to support round-the-clock operations and accommodate the people who make that possible.

Workforce and operations

The refinery employs a large and diverse workforce. This includes:

- Reliance Industries staff managing core operations

- Contract workers for maintenance, construction, and logistics

- Engineers and technicians for process control and unit monitoring

- Support personnel in security, transportation, health, and catering

During its peak construction phases, Jamnagar saw the involvement of over 75,000 workers on site. While the current number is lower, ongoing operations still require a sizable team working in shifts to keep all units running continuously.

On-site township

To support this workforce, Reliance developed a full-fledged township within the refinery area. This residential area includes:

- Housing complexes for staff and their families

- Schools, training centers, and recreational areas

- Medical facilities, including a well-equipped hospital

- Shops, banks, and community centers

This setup minimizes travel time, improves staff availability, and supports retention of skilled personnel.

Internal infrastructure

Apart from the refining units, Jamnagar includes:

- Power generation plants to supply electricity to the site

- Desalination units to provide industrial and potable water

- Effluent treatment facilities for waste management

- Fire safety stations, emergency response teams, and HSE (Health, Safety & Environment) monitoring systems

Jamnagar also uses real-time monitoring and remote control systems in many parts of the facility to reduce human exposure to high-risk areas.

Training and technical development

Reliance operates training programs and certification tracks for its employees and contractors. These focus on:

- Safety and hazard response

- Equipment maintenance and operations

- Process efficiency and optimization

- Environmental compliance

Given the scale and technical complexity of the refinery, continuous upskilling is necessary across roles.

In essence, the Jamnagar Refinery is more than just a processing facility, it’s a self-sustained industrial ecosystem, built to support its people as much as its production goals.

Jamnagar’s economic impact: how the largest refinery powers india and beyond

The Jamnagar Refinery, as the largest refinery in the world, plays a significant role in India’s economy and has far-reaching effects on global energy markets. From exports to employment, its influence extends beyond Gujarat to the national and international level:

National contribution

The Jamnagar Refinery is a major contributor to:

- India’s energy security, supplying a large share of domestic fuel needs

- Fuel exports, which reduce trade deficits and bring in foreign exchange

- Tax revenues, through excise duties, GST, and other levies

- Employment, both directly and indirectly, through support industries and contractors

In some years, the Jamnagar complex has accounted for over 10% of India’s total exports. A substantial portion of this comes from petroleum products like diesel, aviation fuel, and naphtha.

Global trade presence

Jamnagar is one of the few refineries globally with a configuration suitable for large-scale exports. Its marine terminal at Sikka Port enables shipments to over 100 countries. Key markets include:

- Southeast Asia

- Africa

- Europe

- North and South America

Because of its ability to process heavy sour crude and meet Euro V and VI emission standards, the refinery is able to serve both high-specification and price-sensitive markets.

Supply chain and industrial support

The refinery supports a wide network of suppliers, manufacturers, and service providers:

- Engineering and construction companies

- Chemical and catalyst suppliers

- Transportation and shipping partners

- Equipment and machinery vendors

- Local businesses supporting workforce needs

This ripple effect stimulates industrial growth far beyond the refinery gates, especially in western India.

Foreign Investment and Confidence

Jamnagar’s performance has helped reinforce India’s image as a competitive destination for large-scale industrial investment. Its successful operation under Reliance Industries, a private company, showcases the ability to manage and scale high-complexity infrastructure in a developing economy.

Environmental responsibility at the largest refinery in the world

Given the scale of operations at the Jamnagar Refinery, environmental management is a critical aspect of its day-to-day functioning. As the world’s largest refinery, it faces a higher degree of scrutiny on how it handles emissions, waste, and resource use.

- Emissions management and air quality

Jamnagar uses several systems to reduce air pollutants:

- Sulfur recovery units (SRUs) convert hydrogen sulfide into elemental sulfur, limiting SO₂ emissions.

- Flue gas desulfurization and other scrubber technologies are in place to reduce air pollution from combustion processes.

- Low-NOx burners help control nitrogen oxide emissions in fired heaters.

The refinery is configured to produce clean fuels that meet Bharat Stage VI (equivalent to Euro VI) emission norms, which further reduce sulfur and particulate matter in downstream use.

- Water use and treatment

The complex includes:

- Seawater desalination plants to provide water for process needs without relying on local freshwater sources.

- Effluent Treatment Plants (ETPs) that treat wastewater before reuse or discharge.

- Systems for zero liquid discharge in some areas, minimizing freshwater impact.

Water recycling helps manage the needs of such a large industrial site while reducing the load on external water bodies.

- Solid waste and byproduct handling

Refining operations generate solid waste such as:

- Spent catalysts

- Sludge from wastewater treatment

- Petroleum coke (a byproduct of coking units)

These are managed through safe disposal channels or, in some cases, commercial use. Petroleum coke, for instance, is sold as industrial fuel.

- Green zones and land management

Reliance has implemented green belt development in and around the Jamnagar complex to help offset some environmental impact. These planted areas act as dust and noise buffers and support biodiversity in the area.

- Regulatory compliance

The refinery operates under the environmental laws of India, including:

- The Environment Protection Act

- Air (Prevention and Control of Pollution) Act

- Water (Prevention and Control of Pollution) Act

In addition, the refinery follows international standards where applicable, including ISO 14001 for environmental management.

While no large-scale refinery is impact-free, the Jamnagar Refinery has put systems in place to manage emissions, reduce waste, and improve resource efficiency, in line with both local regulations and global best practices.

What’s next for Jamnagar?

As the global energy sector moves toward cleaner alternatives, the Jamnagar Refinery is being repositioned to stay aligned with this transition. Reliance Industries has announced plans to diversify beyond fossil fuels, with Jamnagar playing a central role in that strategy.

Future developments include the integration of green hydrogen, biofuels, and carbon capture technologies into existing operations. These initiatives are part of Reliance’s broader aim to become net-zero in carbon emissions by 2035.

Upgrades to the refinery are also planned to improve energy efficiency and reduce emissions. Some units will be reconfigured to handle a wider variety of feedstocks, enabling more flexibility in production.

In parallel, the focus is gradually shifting toward value-added chemicals and performance materials. This allows the refinery to adapt as global demand for transport fuels levels off and demand for petrochemicals continues to grow.

Jamnagar is also expected to benefit from nearby renewable energy infrastructure, such as solar and wind power, being developed by Reliance in Gujarat.

Together, these moves point to a long-term future where Jamnagar remains active, but with a stronger emphasis on sustainability, diversification, and resilience.

Closing thoughts: what do you think about the world’s largest refinery?

You’ve just explored the Jamnagar Refinery, from how it was built to what it produces, and where it’s headed next. It’s massive, complex, and plays a major role in both India’s economy and the global fuel trade.

But now we’d love to hear from you.

Have you ever seen the Jamnagar Refinery up close? Would you like to visit someday and see how it all works? What surprised you most about how this refinery operates?

Drop your thoughts in the comments below!

You may also like

| Earn U.S dollars in India | 20 most expensive cities in the word |

| Largest cities in Africa | Biggest banks in the world |

| Fastest growing cities in the world |